|

|

|

|

|

|

|

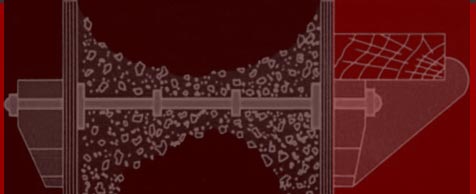

Monowi Concrete Forming System General Erection Procedures:Start all erection with corner "sets" Snap line on concrete floor or footing on one side of the wall and fasten aligner 2x4 plates to floor or footing. Erect this face of wall. Place and nail at intervals to hold sheet to either vertical or horizontal liner. Attach lateral whaler along top for temporary bracing support. At completion of wall plumb and brace for permanent alignment. Install all remaining ties in this wall face using combination or whaler or retainer blocks as desired. This is best done with two persons. The ties should be left reasonably close to a 90 degree angle to the plywood face so that the other side of the wall will fit the ties easily with little adjustment. If the wall more than 8' tall use 2x4 whalers of height required at each vertical joint and join tops with a horizontal plate. Tie in all reinforcing steel. Steel shall not distort ties! Erect second side of wall form by engaging lower row of ties in plywood holes and working up the sheet to each succeeding row of ties. Attach enough retainers as you go up so bottom row does not slip back off. Most holes should line up very easily. Attach horizontal whalers to this side of the wall at approx. 4' centers. Wrap outside corners with 2x4 whalers at each 16" space and run the whaler back at least as far as the last full sheet. Place a nail in this bracket and spike the 2x4 intersection at the corner to contain end pressure and prevent the small corner "sets" from opening up at the joint. Other than the 2x4 whalers at the exterior corners most other 2x4 are only for original alignment and you need to use only as many or few as you are comfortable with. They are NOT required for holding the form together and the locking wedge fit of the retainers and whalers blocks and the resulting interaction of the various plywood sheets usually counteracts any deformity in the various sheets. Walls greater than 8' tall should have whalers and 16" spacing below the top 8' section. Suggested Drilling Pattern:Use pilot sheet and place on top of 6-8 aligned sheets. Drill 3/4" holes. We strongly advise the use of FORM GRADE plywood with two good surfaces. This permits you to reverse the sheet faces at each pour and reverse the strain on the wood grain. This eliminates the "pillowing" pattern often seen on steel or steel lined forms that are used repeatedly with one side exposed. This pattern uses fewest 2x4 whaler brackets and retainers. Upon familiarity with the system users may develop their own drilling patterns to suit particular needs. The "A" pattern uses less ties but requires matching sheet on opposite sides of the wall. Whaler block and 2x4 required on one side of the wall. The "B" pattern is more versatile for either vertical or horizontal setting but requires three more ties per sheet but is less likely to permit "pillowing" unless the contact side is reversed frequently. Where an entire project is not poured at once it is helpful to reuse standard corner "cuts" and set ups and make splices in center of wall runs where succeeding plywood set up can just lap the previously poured wall without further cutting of material. It is useful then NOT to break off a few of the end wall ties so you can tie the newly formed portion back to the poured section. We advise that users make up corner "sets" for differing wall thickness. Only the inside panels of the corner sets need to be adjusted. The outside panels should all be 24", 32", 48" or similar nominal dimensions. Use form release agents or Thompson's water seal (cut 1/2 with diesel oil). When oiling plywood, lay out a number of sheets with edges together to avoid ground pollution with overspray. To remove forms tap whalers and retainers back off; strike tie pin to break OR set shor 2x4 block on top of brackets close to the plywood and strike with sharp blow driving bracket TIGHTER. This should break the tie off behind plywood but you will have to tap out the short end of the tie before reusing the bracket. If adding to end of pour, leave several ties intact to anchor the resulting form to these ties. For walls 8' or greater use vertical pattern shown above. Vertical 2x4 spans both sheets at joint on oneside. On Walls 12' or more high we suggest short whalers between verticals or continuous whalers at the bottom tie and every 32' thereafter up to last 10' of height. "Monowi-Form System"The original self-spacing; non-conductive; non-corrosive plastic form tie system is back on the market!

The most important item in forming after quality is bottom line profit! The cost of the initial tie-material does not have a great impact. It is the saving in labor; support equipment; and time spent erecting and removing that spell SUCCESS. All you need to haul to the job with our system is the tie material, plywood sheets and a few aligner 2x4's! And a hammer! You need many less whalers. You have a rigid form: no pins, cones nail-on plates, etc. to fool with. You can erect 8' vertical or horizontal sections of form work and carry them to location if you widths. The rigid tie clamping system will keep them from collapsing. You can remove the retainer or whaler blocks with one simple hammer blow and at the same time accomplish break back of the tie to the concrete line which means you can lift the form straight up and out. No climbing down in to remove pins, twist off ties or pull nails from retainer plates. Your first use will be the most costly, as you have to purchase enough retainer blocks (two per tie) to fit the size of your job. However these are reusable many times over. You also use standard, easy to obtain 3/4" BB FORMING Plywood. We are presently manufacturing our ties for wall thicknesses of 4, 6, 8, 10, 12, 14, 16, 18, 20, 22, and 24". CAUTIONNEVER use Monowi Forming accessories with LESS THAN BB Grade Yellow Pine or Douglas Fir species, 5 ply FORM plywood of 3/4" thickness on was over 48" high. DO NOT use chip boards, CDX, or other inferior grades as they will NOT distribute and bridge the pressure load evenly between the ties. This could result in a form failure. Pour all concrete in 2-3 ft. lifts. Vibrate each lift separately and do not vibrate down through previous lift. Use maximum 3-4 inch slump concrete. (These are really just STANDARD rules for any concrete form pour!) Tie ends must make 3-POINT contact with retainer and whaler shoulders. If not, you 1/3 of the tensile strength. If whaler or retainer clips have a cracked "keyhole" they should be discarded. If the shoulders become worn or rounded they should only be used near the tops of formwork. Wear ey protection when breaking off tie pin ends. If you are using plasticized concrete - it will increase your form preasure about 400%! You MUST pour in lifts and wait for an initial or partial set.

From 40 years experience in the General Contractor field, we don't belive the Plasti-Form system can be excelled in forming round tanks, basement walls, steel building foundations, bridge and culvert construction, wing walls, retainer walls and many commercial structures. |

||||||||||

|

|

|